DEATHS

OTHERS

Pensioners: Berton D. Cornell, telegrapher-clerk, San Diego & Arizona Eastern.

March, Page 10-13

They Call It 'Plaster City'

U.S. Gypsum's unique plant in California's Imperial Valley depends on fast, efficient SP service.

Plaster City is a complex of silvery buildings set in the powdery white landscape of California's Imperial Valley, about 16 miles west of El Centro. This area, well below sea level, was the bottom of a sea eons ago.

LEFT: U. S. Gypsum employes tie down a shipment of wallboard, which will travel aboard an SP bulkheaded flatcar, protected by a coating of polyethelyne film.

Today it is the location for a United States Gypsum plant that manufactures plaster, plaster board and wallboard for the construction industry. Refined gypsum is also produced for use in cement and as a soil conditioner in agriculture.

Gypsum is so widely used in this urban age that it is difficult to get more than a few feet away from some gypsum product, whether you are in a house, an apartment or an office. There are three tons of it in the average home-and for good reason.

"Gypsum is a durable substance," says Richard W. Deneke, works manager for USG at Plaster City. "What's more, it won't burn and it serves as an effective barrier against fire."

Deneke explains that water entrapped in the chemical structure of wallboard made from gypsum helps prevent heat from penetrating. A 1,700 degree flame would take an hour before it could transmit its heat to the other side of a half-inch thick sheet of wallboard, he says.

LEFT: This complex of silvery buildings is U. S. Gypsum's plant at Plaster City. It manufactures plaster, plaster board, wallboard, and refined gypsum.

Although gypsum has found wide use in modern times, it is one of the oldest known building materials. The pyramid of Cheops, built before 3,000 B.C., contains gypsum decorations. Vases and other artifacts made from this substance have been dug from the ruins of ancient cities, and many church masterpieces of the Italian Renaissance are frescoes painted on gypsum plaster walls.

The material we refer to as gypsum is hydrous calcium sulphate, a mineral containing about 40 per cent water in its natural state. After it is mined, the raw rock is crushed into gravel and cooked in a huge tube-shaped furnace called a rotary calcinator, which removes some of the water. Further crushing and cooking result in a chemical change that produces calcined gypsum, a fine white powder commonly designated plaster of Paris.

"Some measure of the gypsum industry," Deneke says, "is the fact that 12 million tons of it are mined every year in the United States - enough to fill a freight train stretching more than 2,400 miles."

The man who helps Southern Pacific serve the considerable transportation needs of the Plaster City plant is Leo M. Ford, district freight and passenger agent at El Centro.

LEFT: Narrow gauge railroad operated by U. S. Gypsum Co. carries raw gypsum from mine to Plaster City.

"We handle virtually all outbound products of the plant and some inbound materials used in the processing," Ford says. SP box cars bring in giant rolls of paper that form the two faces of the wallboard. Finished wallboard leaves the plant on bulkheaded flatcars, while bagged gypsum products are shipped out in box cars.

Ford, a veteran railroader, says that the advent of mechanical loading by lift trucks has helped speed the distribution of the plant's production, which some years ago was loaded and unloaded by inefficient hand methods.

"With modern material handling methods, shippers and receivers like U. S. Gypsum can load and unload much more rapidly than was possible before," Ford points out. "In addition, our newer cars are longer and have higher bulkheads for greater carrying capacity. The railroad has answered the construction industry trend toward larger sizes of wallboard by building the bigger cars that can handle this type of traffic."

Industry sources agree that high capacity cars are an important factor in the more widespread use of wallboard. One modern flatcar, for example, can carry enough wallboard to build all the interior walls for 10 houses.

Wallboard production at Plaster City requires a building three quarters of a mile long. It houses what Deneke calls "the board line," a moving belt on which wet plaster is sandwiched between two sheets of paper, baked in huge kilns and cut into standard lengths.

LEFT: El Centro DF&PA Leo Ford, left, checks details of shipment with Richard W. Deneke, works manager at Plaster City.

"The whole process takes from 45 minutes to an hour," Deneke says.

Products made from a powdered gypsum base are put in bags at the plant and shipped to customers who find a surprising variety of uses for the versatile compounds - in plastering, dental and medical casts, crayons, plate glass, paper, industrial molds, cement and as a combination fertilizer-soil conditioner.

Loaded cars leave the plant over the San Diego & Arizona Eastern, a Southern Pacific subsidiary. Shipments go to San Diego, Phoenix, Tucson, Los Angeles and San Francisco. Trainmaster J. L. Green in the office of SD&AE Superintendent W. B. Barker is the operating officer responsible for supplying empty cars at Plaster City and for moving loads out on schedule.

Ceiling-high stacks of wallboard await shipment. DF&PA Leo Ford, left, chats with Burt Thompson, U. S. Gypsum Company plant personnel manager.

One unique aspect of the U. S. Gypsum operation is the narrow gauge railroad owned by the company. Averaging three trips a day, the single train on the line shuttles over 26 miles of track across the desert between the mine at Split Mountain and the processing plant. In comparison, the trip would be almost 80 miles over the highway.

The narrow gauge has a roster of three locomotives - all of them diesel since 1956, when the last steam engine was retired. Two units power the 20-car train of 50-ton open hopper cars, while the third diesel is held in reserve at the plant. Cars on USG's little railroad reflect a high standard of maintenance with their sleek gray sides and air operated bottom dump gates. Loading at the mine and unloading at the plant is facilitated by conveyor belts.

The gypsum train runs over rails only 36 inches apart, compared to standard gauge of 4 feet 8 ½ inches. For an engineer from a busy railroad like SP the trip would represent the ultimate in carefree operation: there are no other trains on the track, no switches, no signals, no grade crossings and no other people living in the vicinity.

Before the railroad and the processing plant existed, Indians in the area used the mountain of "white rock" to make pottery and cooking utensils. Then in the late years of the 19th century a pair of El Centro residents filed claim to the mine. Quarrying operations began and the railroad was built, but it was not until 1924 when Pacific Portland Cement Company bought the ore deposits and the railroad loading facilities that manufacturing began on any sizable scale.

United States Gypsum acquired the property in 1945. Since then, extensive modernization and expansion of the facilities have been accomplished as the company foresaw an increasing demand for its products.

"The management and employes at Plaster City are looking forward to a healthy growth for their industry," Leo Ford says. "And we at Southern Pacific will be doing our part to keep pace with their changing transportation needs by offering the best in modem railroad equipment and service."

LEFT: U. S. Gypsum's crushing plant and stockpile are located near its quarry in a remote and rugged part of California's Imperial Valley.

RIGHT: Miles of paper on these rolls will be used as facing for wallboard.

September, Page 20

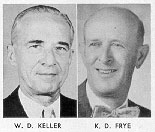

Frye Succeeds Keller

Willard D. Keller, district freight and passenger agent of Southern Pacific, and

traffic manager of the San Diego and Arizona Eastern Railway Company, with headquarters

at San Diego, has retired after completing a 50-year railroading career. .

Named to succeed him was Kenneth D. Frye, former SD&AE traveling freight and

passenger agent at San Diego.

Keller, who joined SP at Los Angeles in 1914, had been top traffic man at San Diego

since 1957.

Willard D. Keller, district freight and passenger agent of Southern Pacific, and

traffic manager of the San Diego and Arizona Eastern Railway Company, with headquarters

at San Diego, has retired after completing a 50-year railroading career. .

Named to succeed him was Kenneth D. Frye, former SD&AE traveling freight and

passenger agent at San Diego.

Keller, who joined SP at Los Angeles in 1914, had been top traffic man at San Diego

since 1957.

October, Page 29

RECENT RETIREES

OTHERS

John A. Gamble, yard clerk, San Diego & Arizona Eastern.

October, Page 30

DEATHS

OTHERS

Clement W. Roberts, section foreman; Samuel W. Sering, switchman, both of San Diego & Arizona Eastern.

November, Page 31

DEATHS

OTHERS

Pensioners: Edward Enright, locomotive engineer, San Diego & Arizona Eastern.

Back to SP Bulletins

Back to SP Bulletins