Return to the San Diego Railroad Museum

This page last updated 2/24/99

| Model | Bore | Stroke | Cyl. Disp | Rated RPM |

|---|---|---|---|---|

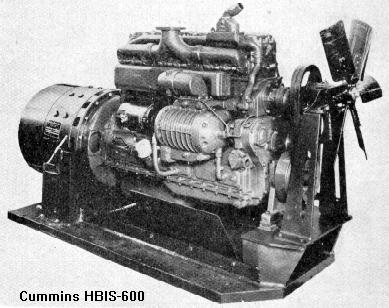

| HBI600 | 4.875" | 6" | 112 cu. in. | 1800 |

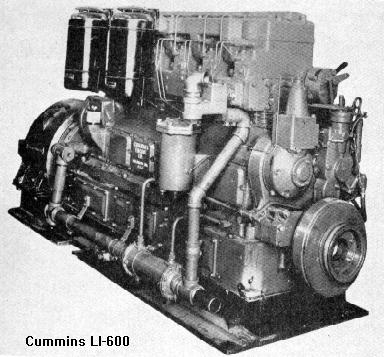

| LI-600 | 7" | 9" | 346 cu. in. | 1000 |

Photos and text from "Diesel-Electric Locomotive", Foell and Thompson, 1946.A distinctive feature of the Cummins Diesel engine is the fuel system which is manufactured solely by Cummins and is used exclusively on its engines. The fuel is pumped and metered, simultaneously, from a single unit direct to the injectors with a line pressure of only 120 to 150 lb. per sq. in. Special handling of the fuel at the injector provides pre-heating and partial vaporization prior to actual injection.

Cylinder Block and Oil Pan: The cylinders are cast enbloc of nickel-iron, while the oil pan, of wet-sump type, is made of cast iron.

Cylinder Heads: The heads are of cast iron, each head serving two cylinders. There are 4 valves per casting unit, two inlet and two exhaust, with an injector between each pair. The valves are of overhead type, operated by rockers which pivot on an overhead shaft. The injector nozzle plungers are operated from this same shaft by an additional rocker in line with the valve rockers, thus providing 3 rocker levers for each engine cylinder.

Cylinder Liners: The liners are the wet type, and removable. They are constructed of nickel-chromium cast iron with a high carbon content. The liners are positioned at the top by a ground joint and held in place by the cylinder head. They are sealed at the bottom by endless packing rings.

Crankshaft: The crankshaft is a drop-forging of nickel molybdenum steel with Tocco-hardened journals. There are 7 main journals of 4 1/2 in. diameter. The crankpin journals are 3 1/4 in. in diameter.

Main and Connecting Rod Bearings: These bearings are of the Precision type, steel backed, with copper-lead bearing faces. Shell-type construction permits easy removal and replacement.

Connecting Rods: The connecting rods are forged, of chrome-molybdenum steel, and drilled for pressure lubrication to the Piston-pins.

Pistons: The pistons are cast of chrome-nickel iron, and cam ground. There are three compression rings above the piston-pin and two oil-control rings in the skirt. A feature of these pistons is the Cummins cup wiper which is screwed into the center of the top surface of the piston head. The purpose of the wiper, into which air is forced on the compression stroke, is two-fold: To act as a blower to keep the injector nozzle clean, and to assist in combustion chamber turbulence, as the entrapped air rushes out into the main combustion space.

The wiper is a hollow cup with an opening at the top. During the compression stroke, the air within the cup is compressed to the maximum pressure developed in the combustion chamber. As the piston starts downward on the power stroke, the pressure within the cylinder is reduced and the air within the cup, being of higher pressure, blows out into the cylinder, in the direction of the injector nozzle tip. Since actual injection and firing of the fuel takes place between 49 degrees B.T.C. and 19 degrees A.T.C., the air injected from the cup tends to clean off any unburned fuel remaining on the injector tip and prevents the formation of hard carbon. It is claimed that this process keeps the injector nozzle outlet in a clean and most efficient working condition.

The piston-pins are of full-floating type and are manufactured of electric steel. Pressure lubrication is supplied through the rifle-drilled connecting rod.

Valves: The engine valves are of heat-resisting, silichrome steel. Exhaust valve seats are of Stellite and are a shrink fit in the head. Valve guides are cast iron. Valve springs are high-manganese spring steel.

Supercharger: Although the supercharger is not used on the Type H engine it will be described because of its application on some other models. It is of the Roots blower type. The supercharger is interposed between the generator and its drive gear which, in turn, is driven by a gear train consisting of the camshaft gear and an idler gear.

A preheater is employed on supercharged engines for starting at sub-freezing temperatures. This consists of an assembly which throws a flame directly into the intake air. Fuel is forced into the airstream through a nozzle and is ignited by a continuous spark supplied by a pair of electrodes. Pressure for forcing the fuel through the nozzle is supplied, by a hand pump, while a 12-volt spark coil of the vibrator type supplies the spark. A snap switch in the primary of the spark coil and battery is provided to turn the spark on and off. Preheaters are not used on standard, unsupercharged engines, as the higher compression ratios of this type unit affords easy starting, even at reasonably low temperatures.

Back to the Diesel Roster

Table

Back to the Diesel Roster

Table