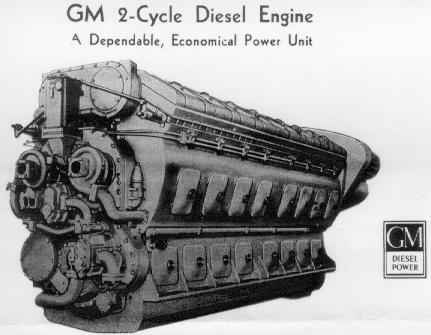

The following is from a 1938

EMC advertisement.

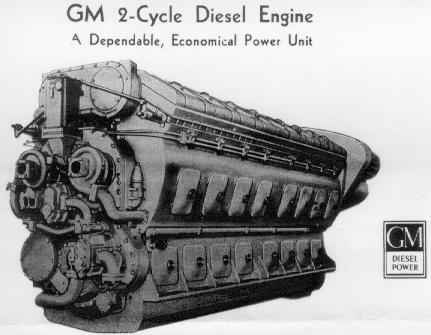

The following is from a 1938

EMC advertisement.

| Bore | Stroke | Cyl. Disp | Rated RPM | Idle RPM | Cyl. scavenging |

|---|---|---|---|---|---|

| 8.5" | 10" | 567 cu. in. | 800 | 275 | Roots type blower |

The following is from a 1938

EMC advertisement.

The following is from a 1938

EMC advertisement.

The GM Diesel is a rugged and compact, uniflow, two-cycle, solid-injection engine. With every down stroke a power stroke, the engine is capable of rapid and smooth acceleration, so very essential in railway service. The cylinders are arranged in two banks forming a 45-deg. Vee and are combined in one unit with the crankcase by welded steel construction, combining light weight and exceptional strength.

Cylinder liners are heat treated cast iron, ground to a mirror finish on the inside. The liners are double-walled with cooling water space between and with transverse air-intake ports opening into an air box which forms a part of the crankcase. Cylinder heads are bolted to the liners independently of the studs which hold the assembly in the blocks.

Pistons are pearlitic malleable iron with the head recessed at the top to form part of the combustion chamber and help create turbulence during fuel injection, deeply ribbed on the underside for strength and to provide additional cooling. Pistons are oil cooled by an oil spray through a separate pump provided for this purpose. Pressure lubrication is supplied to all important points and the oil is properly conditioned by passing through filters and cooler.

Connecting rods are drop forgings of fork and plain rod construction to eliminate cylinder offset and improve bearing conditions. The two-cycle principle permits a simple cap design, allowing removal through the cylinder liners of connecting rods with a large crankpin diameter. The carbon steel crankshaft is drop forged with electro-hardened journals, permitting the use of copper alloy crankpin bearings and special babbitt main bearings. All bearings are precision made, eliminating hand fittings.

The Unit Fuel Injection System employed is a principal and patented feature of GM Diesels. Each cylinder is fitted with an individual injector unit which constitutes an independent and complete injection system operated from the overhead camshaft. Complete and accurate control of the fuel injection, timing, and atomization, combined with complete blower scavenging, result in high efficiency, clear exhaust and smooth operation.